Production facilities at Raffinerie Heide

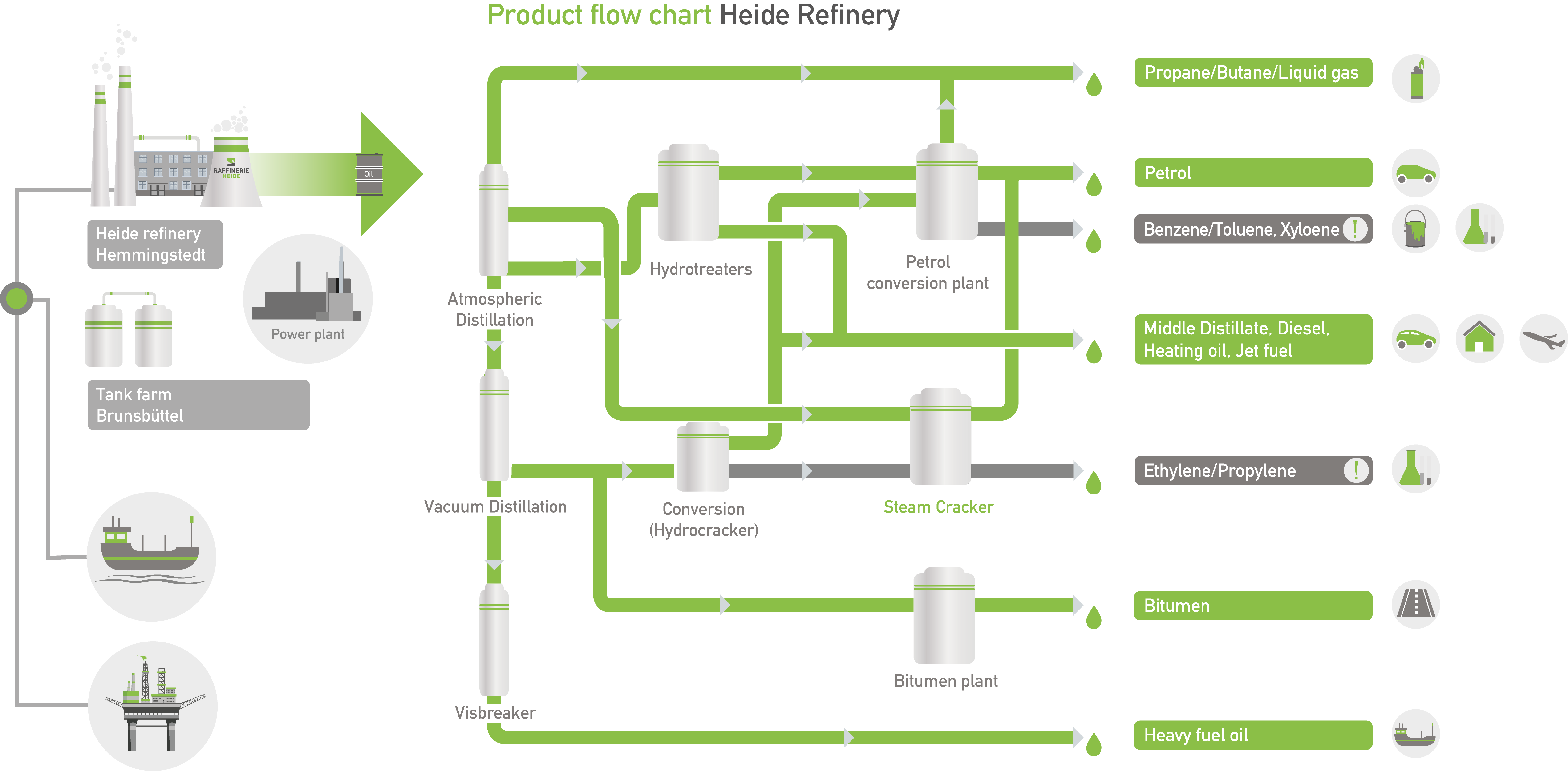

A refinery comprises three processing areas: separation, conversion and refinement. Improvements over recent decades, particularly in the field of conversion, have led to a massive growth in yields.

Whereas conventional distillation produces up to 50% heavy fuel oil, during the reconditioning of this residue the structure of the individual molecules is changed in a way that allows greater quantities of high-quality products such as petrol and middle distillate to be produced from the crude oil.

For historical reasons, Raffinerie Heide has always refined high-density crude oil .

What this means for our technical setup is that ever since the 1950s we have had to regularly make major investments in our production facilities and processes to adapt the refinery to the latest technological innovations.

The Hydrocracker and chemicals

as a guarantee of success

The Raffinerie Heide is one of the high-conversion refineries. These are characterized by the use of so-called hydrocrackers, which are technically the most elegant and flexible, but also the most complex conversion process.

With the construction of the HC in 2000, the conversion of the refinery could be increased. Thanks to the combination of chemistry and high conversion, the Raffinerie Heide is flexibly set up in order to be able to react to any market situation.

Hydrocracking

Hydrocracking involves breaking down the oil’s molecular chain by adding hydrogen and applying high pressure. This has the advantage of allowing the yield to be nudged in the required direction, meaning above all that our utilisation rate is significantly higher than that of conventional refineries.

The modern refinery

Nelson-Index 9,7

European facilities achieve an average rating of 6.5.

We are proud to say that Raffinerie Heide has score of 9.7 on the Nelson Index, making us one of the most flexible and modern refineries in Germany.